Stadium Floodlighting Galvanized Steel/Metal High-Mast Solar Street Light Pole with Factory Price

Package size per unit product 3000.00cm * 150.00cm * 150.00cm Gross weight per unit product 3000.000kg Galvanized street

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | DG-30 |

| Type | Round |

| Design Standard | GB50017 |

| Material Standard | GB/T 700 |

| Welding Standard | GB/T12467 |

| Galvanizing Standard | GB/T13912 |

| Coating Standard | Jg/T 3045.2 |

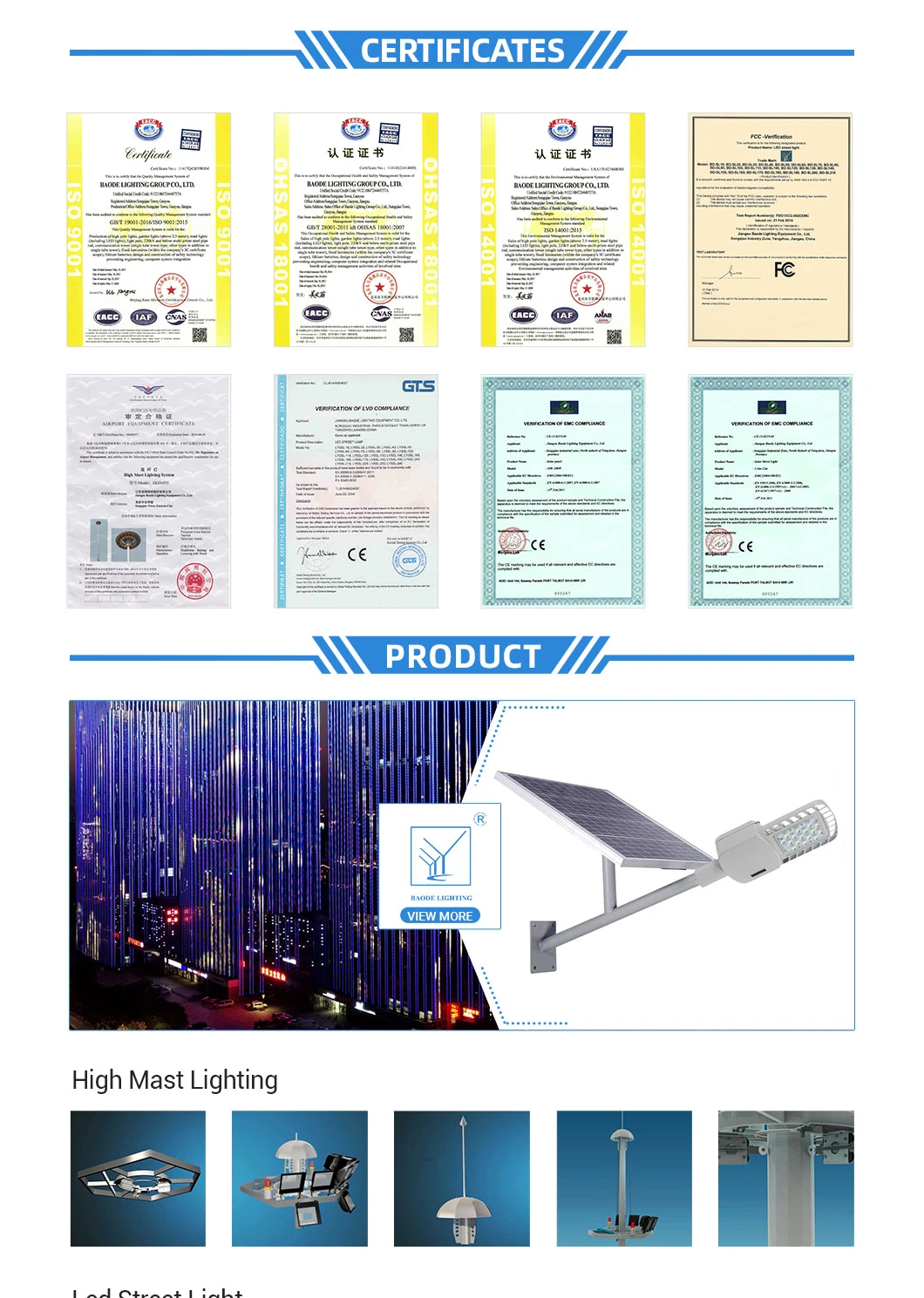

| Quality Management System | ISO 9001:2008 |

| Shaft Shape | Round Conical/Octagonal Tapered |

| Shaft Thickness | 6mm |

| Flange Plate | 1050*1050*30mm |

| Anchor Bolts | 12-M30-2000, Detachable |

| Transport Package | Bubble Film or Felt Cloth |

| Specification | 260-600 |

| Trademark | Luyou |

| Origin | Jiangsu, China |

| HS Code | 7308900000 |

| Production Capacity | 40000 Piece/Year |

Packaging & Delivery

Package size per unit product 3000.00cm * 150.00cm * 150.00cm Gross weight per unit product 3000.000kgProduct Description

Galvanized street lighting pole with CE certificate(DG-8)Product Description

Material

Q235 high quality mild steel

Mounting Height

3-12M

Shape of Pole

Round conical; Octagonal conical; Straight square; Tubular stepped; Polygonal

Shafts are made of steel sheet that folded into required shape and welded longitudinally by automatic arc welding machine

Brackets

Single or double brackets are in the shape and dimension as per customers requirement

Welding

Welding confirms with international welding standard of CWB

Base plate mounted

Base plate is square or round in shape with slotted holes for anchor bolt and dimension as per customers requirement

Ground mounted

The length buried underground as per customers requirement

Galvanizing

Hot dip galvanization with thickness of 80-100 µm average

customized service or design service

Offered

DIFFERENT SHAPE OF POLEWe offer various shape of pole for your choice, including round straight, round tapered, square straight, square conical, and octagonal tapered steel pole.

TECHNICAL PARAMETER SHEET

OCTAGONAL POLES - STANDARD SPECIFICATIONS | ||||||||||

Height (m) | Top Diameter (mm) | Bottom Diameter (mm) | Shaft Thick (mm) | Base Plate | Foundation Bolt | |||||

Dimensions (mm) | Yield Stress (N/mm²) | J-Bolt (mm) | Yield Stress (N/mm²) | Pitch Circle Diameter (mm) | Bolt Length (mm) | Projected Bolt Length (mm) | ||||

3 | 70 | 130 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 450 | 80 |

4 | 70 | 130 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 450 | 80 |

5 | 70 | 130 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 600 | 80 |

6 | 70 | 130 | 3 | 220*220*12 | 345 | 4-M20 | 280 | 205 | 600 | 100 |

7 | 70 | 130 | 3 | 220*220*14 | 345 | 4-M20 | 280 | 205 | 700 | 100 |

8 | 70 | 135 | 3 | 225*225*16 | 345 | 4-M20 | 280 | 210 | 750 | 100 |

9 | 70 | 155 | 3 | 260*260*16 | 345 | 4-M24 | 280 | 250 | 750 | 125 |

10 | 70 | 175 | 3 | 275*275*20 | 345 | 4-M24 | 280 | 270 | 750 | 125 |

11 | 90 | 210 | 3 | 300*300*20 | 345 | 4-M24 | 280 | 300 | 850 | 125 |

12 | 90 | 240 | 3 | 320*320*20 | 345 | 4-M24 | 280 | 325 | 850 | 125 |

CONICAL POLES - STANDARD SPECIFICATIONS | ||||||||||

Height (m) | Top Diameter (mm) | Bottom Diameter (mm) | Shaft Thick (mm) | Base Plate | Foundation Bolt | |||||

Dimensions (mm) | Yield Stress (N/mm²) | J-Bolt (mm) | Yield Stress (N/mm²) | Pitch Circle Diameter (mm) | Bolt Length (mm) | Projected Bolt Length (mm) | ||||

3 | 75 | 105 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 450 | 80 |

4 | 75 | 115 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 600 | 80 |

5 | 75 | 125 | 3 | 200*200*12 | 240 | 4-M16 | 280 | 200 | 600 | 80 |

6 | 75 | 135 | 3 | 225*225*12 | 345 | 4-M20 | 280 | 210 | 600 | 100 |

7 | 75 | 145 | 3 | 240*240*12 | 345 | 4-M20 | 280 | 235 | 700 | 100 |

8 | 75 | 155 | 3 | 240*240*14 | 345 | 4-M20 | 280 | 235 | 750 | 100 |

9 | 75 | 165 | 3 | 275*275*16 | 345 | 4-M24 | 280 | 270 | 850 | 125 |

10 | 75 | 175 | 3 | 275*275*16 | 345 | 4-M24 | 280 | 270 | 850 | 125 |

11 | 85 | 195 | 3 | 300*300*16 | 345 | 4-M24 | 280 | 300 | 850 | 125 |

12 | 96 | 216 | 3 | 320*320*16 | 345 | 4-M24 | 280 | 300 | 850 | 125 |

DIFFERENT SHAPE OF LAMP BRACKET

We offer various shape of lamp brackets for your choice, including single arm and double arms.

Hot Dip Galvanizing is a corrosion protection process and has been successfully applied for more than 150 years. The research and Practical experience have established that the corrosion resistance of galvanized steel reinforcement is superior to uncoated steel and any other type of protective measures. The corrosion protection by the galvanized coating ensures that the design strength of concrete is maintained and the possibility of surface rust staining and eventual corrosion of reinforcement of concrete are removed. Galvanizing provides a tough, metallurgical bonded zinc coating that entirely encloses the steel and preserve it from the corrosive action of the atmosphere and providing protection that does not affect the properties of steel and the strength of the reinforcement bar remains same. Hence, this process or method is secured and reliable. The process of Hot Dip Galvanizing is taken place in the fully automated temperature controlled Galvanizing bath, & Quenching Tank is also controlled through cooling Tower by Auto Control System.

P OWDER COATING FINISH

Surface Preparation

Prior to beginning the powder coat process, each shaft section is completely cleaned using a system called steel shot blasting. Steel shot blasting is the process by which each section is sent through a wheelabrator. The wheelabrator provides a massive blasting of No. 280 steel shot directed at the surface to be cleaned. This process meets the Steel Structures Painting Council Surface Preparation Specification No. 6 (SSPC-SP6).

Powder Coat Application

Electrostatic spraying is the most common method for applying powder. The powder is fed pneumatically from a reservoir to a spray gun where a low amperage, high voltage charge is imparted to the particles. The parts to be coated are grounded so the charged particle will seek the oppositely-charged metal surface. This method will produce a uniform, monolithic, fusion- bonded finish. The powder coated steel parts will then go through an oven where the resins, pigments and other reactive agents cross link to produce a high molecular weight binder system, resulting in a tough durable coating.

Quality

Powder coating was developed for outstanding weather ability, toughness and architectural aesthetics. The high molecular weight of powder coating provides better corrosion, impact, chip and scratch resistance versus using the brush on paint method. Baode Lighting will provide a protective foam wrap on each pole section to protect the surface during the shipping process.TRANSPORTATION

EXPORT AND MARKET SHARE

Apart from the Chinese market, BAODE LIGHTING cater to international markets as well. BAODE LIGHTING have projects in the below countries, including Bosnia and Herzegovina, Democratic People Republic of Korea, Federal Democratic Republic of Ethiopia, Federal Republic of Nigeria, Kingdom of Cambodia, Kingdom of Morocco, Kingdom of Saudi Arabia, Kingdom of Spain, People's Republic of Bangladesh, Republic of Albania, Republic of Angola, Republic of Botswana, Republic of Chad, Republic of Chile, Republic of Costa Rica, Republic of Djibouti, Republic of India, Republic of Kazakhstan, Republic of Kenya, Republic of Korea, Republic of Latvia, Republic of Poland, Republic of Singapore, Republic of the Congo, Republic of the Philippines, Republic of Uganda, Republic of Zambia, Russian Federation, State of Libya, State of Qatar, The Hashemite Kingdom of Jordan, United Arab Emirates and United Republic of Tanzania, to name a few. Why our poles?

One-stop Service

You can find solutions for almost all outdoor lighting from us, like street lighting, square lighting, landscape lighting, traffic lighting and commercial lighting and so on.

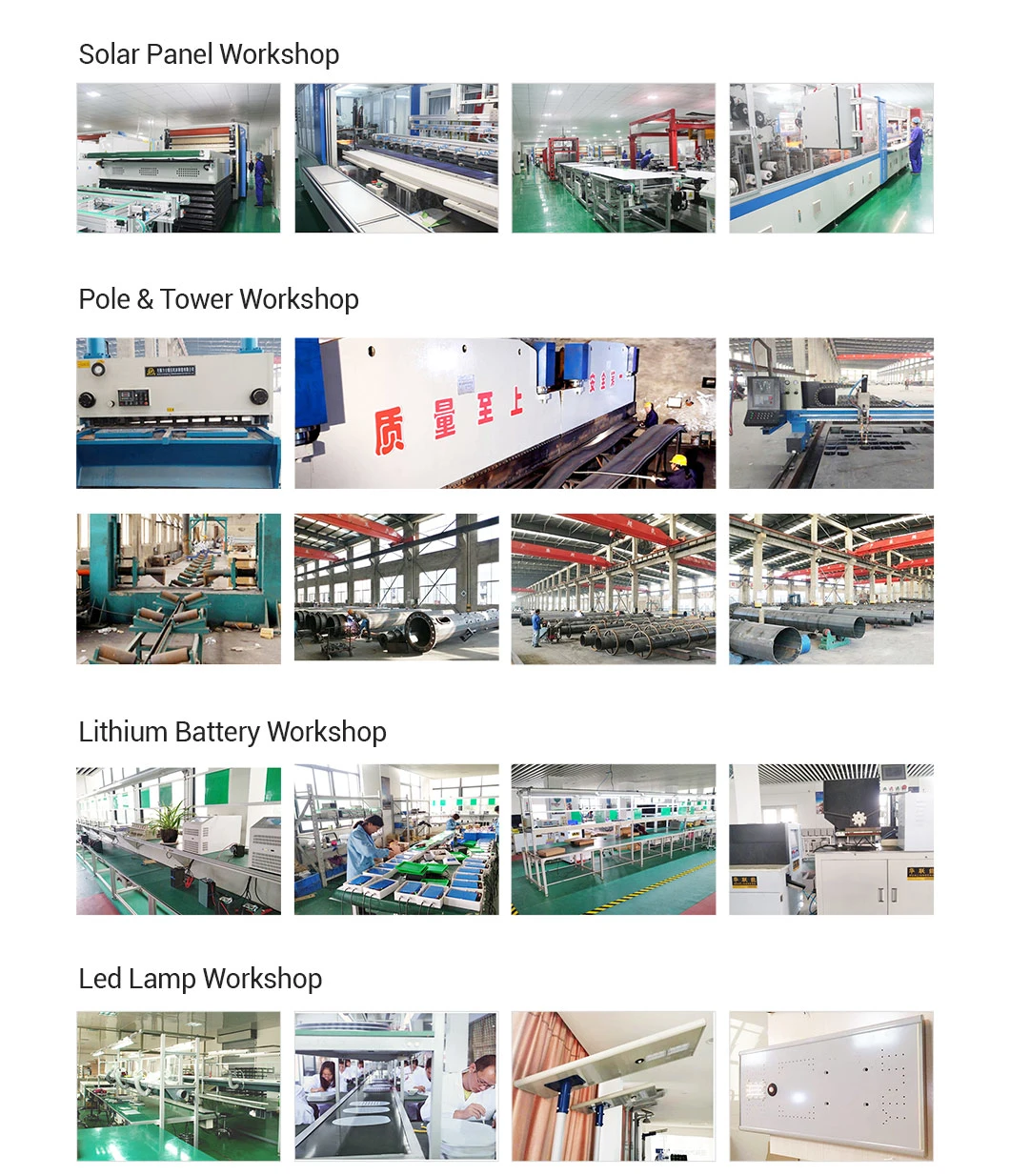

Vertically Integrated Production System

You will enjoy high-quality product with cost-effective price from us because we manufacture most of the main components from LED source, light fixture, solar panel, pole and even painting powder to control the cost and quality.

15 Years Manufacturing Experience

Since 1998, we have started manufacturing street lighting. The 15 years' experiences have been a persuasive insurance for us to offer reliable products.

Large Factory with Complete Facility

We have 400 staffs with factory area 6000 m2. We also equipped with complete production and testing equipments, such as Steel Pole Rolling Machine, Spray Machine, Pressure Machine, Integrating Sphere, Lighting Simulating Machine and Weather-ability Testing Machines, etc . .

Advanced Technology

Our 60 experienced engineering team work with the PV institute of Shanghai FUDAN University , Shenzhen Foxconn to R&D outdoor lighting products. We have obtained over 20 national patents and built our own brand LUYOU.

Cost Efficiency

Manufacturing main components to save cost. BAODE manufactures the solar panel, light fixture and pole to control the cost and quality.

Factory outlet

There's no middleman between the manufacturer BAODE and domestic and oversea buyers.

Company Information

Related Products

-

![3m~20m Conical Octagonal Square Tubular Street Light Pole]()

3m~20m Conical Octagonal Square Tubular Street Light Pole

-

![LED Lawn Spike Light IP66 Projects Lighting 12V AC/DC, DC24V]()

LED Lawn Spike Light IP66 Projects Lighting 12V AC/DC, DC24V

-

![Solar Manufacturer Supplier CE 2000W/1000W/800W/600W/500W/400W/300W/200W Sensor LED Street Outdoor Camera COB Lawn Garden Wall Flood Garden Road Light Factory]()

Solar Manufacturer Supplier CE 2000W/1000W/800W/600W/500W/400W/300W/200W Sensor LED Street Outdoor Camera COB Lawn Garden Wall Flood Garden Road Light Factory

-

![LiFePO4 1000W Portable Solar Generator Solar Power Banks Lithium Ion Batteries Solar Energy Storage]()

LiFePO4 1000W Portable Solar Generator Solar Power Banks Lithium Ion Batteries Solar Energy Storage